The durability of an electrical cord depends on several factors, including its quality, construction, and usage conditions. Electrical cords are designed to be reasonably durable and safe for regular use, but their longevity can vary depending on the following factors:

Quality of Materials: The materials used in the construction of the cord play a significant role in its durability. High-quality electrical cords are made with robust materials that can withstand wear and tear, such as heavy-duty insulation, copper conductors, and durable outer jackets.

Flexibility: The ability of the cord to flex and bend without damage is crucial for its durability. Cords with flexible materials and good strain relief are less likely to develop internal breaks or fractures due to repeated bending and movement.

Temperature and Environmental Conditions: Electrical cords should be used within their specified temperature and environmental limits. Extreme heat, cold, moisture, or exposure to chemicals can degrade the cord's insulation or outer jacket, reducing its durability.

Load and Current Capacity: Using the cord within its rated current capacity is essential for its longevity. Overloading the cord with excessive electrical current can lead to overheating, insulation breakdown, or even fire hazards.

Usage Frequency: The more frequently an electrical cord is used and handled, the greater the wear it will experience. Cords used in high-traffic areas or in industrial settings may wear out faster than those used infrequently.

Protection and Maintenance: Proper care and maintenance can extend the life of an electrical cord. Avoiding kinks, knots, and sharp bends, and storing the cord properly when not in use can help prevent damage.

Tension Relief: Tension relief mechanisms, such as grommets or cord grips, can protect the cord from damage near the plug or connection points.

External Hazards: Protection from physical damage, such as crushing, cutting, or exposure to sharp objects, is crucial for the cord's durability.

Safety Certifications: Cords with recognized safety certifications (e.g., UL, CSA) are more likely to be made to higher standards and exhibit better durability.

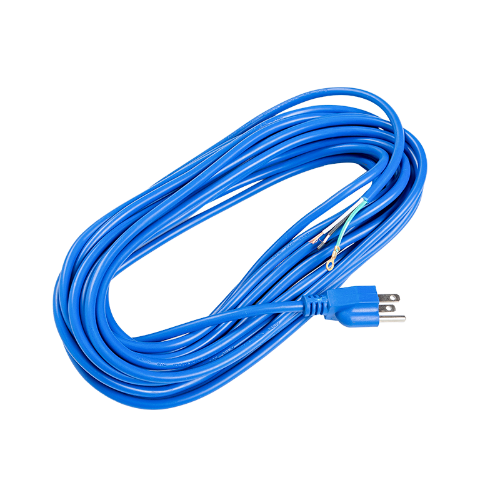

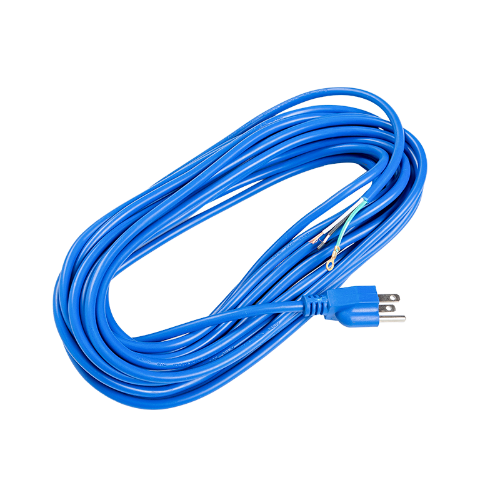

EU standard 3-pin copper core wire plug power connection cable, H05VV-F 3X1.0mm², Grade of 13A/250V.Good conductivity, tight bonding, not easy to fall off, 100% all copper core wire, small resistance, better conductivity, more power saving, wide range of universal interface, long lifetime, can be customized according to the needs of guests with different specifications.Suitable for Holland, Europe, France, etc. The other end has been stripped off, which can be used for plug-in boards, dishwashers, electric fans and other household appliances, adaptable.

EU standard 3-pin copper core wire plug power connection cable, H05VV-F 3X1.0mm², Grade of 13A/250V.Good conductivity, tight bonding, not easy to fall off, 100% all copper core wire, small resistance, better conductivity, more power saving, wide range of universal interface, long lifetime, can be customized according to the needs of guests with different specifications.Suitable for Holland, Europe, France, etc. The other end has been stripped off, which can be used for plug-in boards, dishwashers, electric fans and other household appliances, adaptable.

English

English русский

русский